What Is a Ignition Switch?

A construction equipment ignition switch is a heavy-duty electrical control device that manages power flow from the battery (typically 12V or 24V) to the engine, electrical systems, and safety circuits. Unlike automotive ignition switches, these units are engineered for continuous exposure to harsh jobsite environments such as mines, farms, and large construction zones.

Key Characteristics of Heavy Machinery Ignition Switches

- Ruggedized construction: Fiber-reinforced nylon or cast zinc housings with IP65+ protection against dust and water.

- High-durability contacts: Silver-alloy contacts rated for up to 100,000 cycles under vibration.

- Integrated safety interlocks: Prevent engine start unless safety conditions are met.

- Diesel preheat capability: Dedicated glow plug preheat position for cold starts.

Where Ignition Switches Are Installed on Heavy Machinery

- Dashboard or control panel: Most common in John Deere tractors, JCB backhoes, and Volvo excavators—mounted on the cab’s dashboard or side control panel, shielded from direct impact and debris.

-

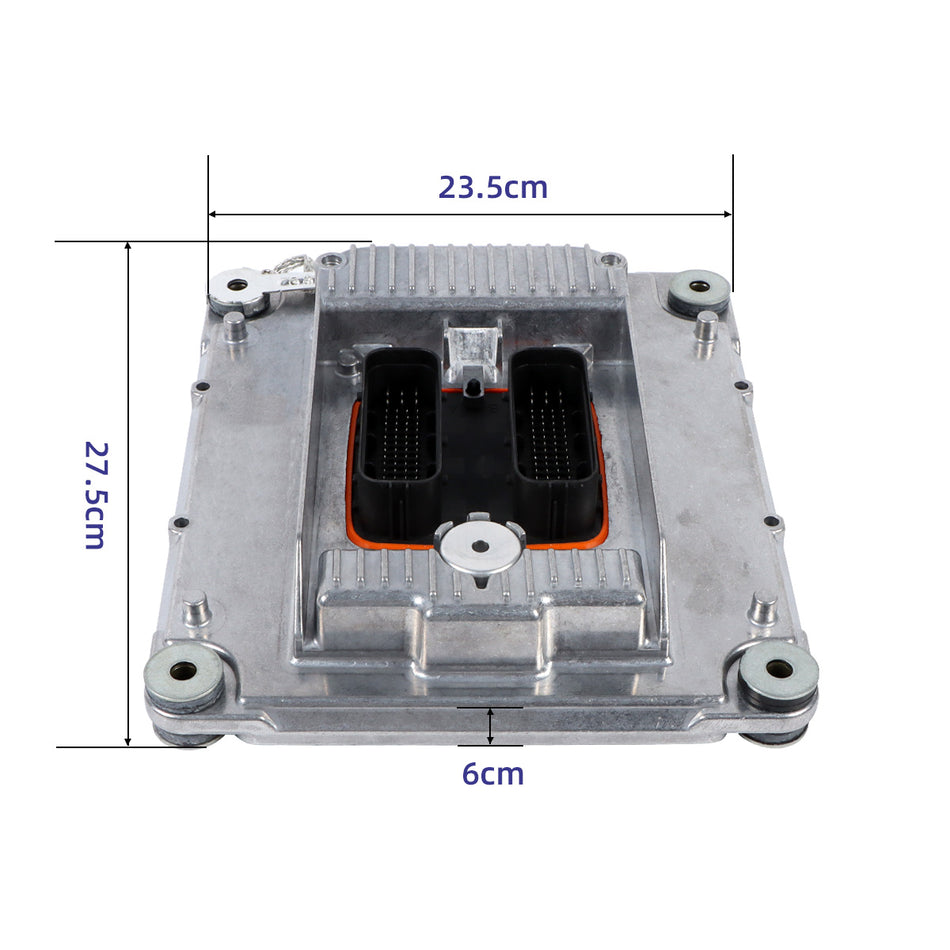

Integrated control modules:

In machines like Komatsu D65 bulldozers, the ignition switch is part of a modular control assembly that combines lighting, hydraulic controls, and safety buttons for streamlined operation.

Ignition Switch for Several Major Brands

330262 1532371C2 10 Pins Ignition Switch for JCB JCB200 JCB220 ExcavatorHow a Construction Equipment Ignition Switch Works

Heavy machinery ignition switches typically operate through five key positions to safely manage diesel engine startup and system activation:

-

Off: The default position when the key is removed. It serves power to all systems—engine, hydraulics, accessories—to prevent battery drain and unauthorized operation.

-

Accessory(Acc) Position: Supplies power to non-essential accessories without engaging the engine or safety systems: cab lights, radio, USB ports, and diagnostic tools. This is useful for inspecting the machine or charging devices without starting the engine—critical for pre-job checks on Volvo loaders.

-

On (Run) Position: Activates the machine’s critical systems and initiates safety interlock checks. Power flows to: dashboard gauges, fuel pump, hydraulic system sensors, and the ECU.

-

Preheat: Sends power to glow plugs based on ambient temperature.

- Start: Engages the starter motor once all conditions are met.

Integration with Electrical & Safety Systems

-

Battery & Alternator: Wired directly to the 12V/24V battery (positive terminal) for power. Once the engine runs (On position), the alternator recharges the battery, monitored by the switch to prevent overcharging.

-

Safety Relays & PLC: The switch sends signals to safety relays (per IEC 62061 standards) that cut power if interlocks fail (e.g., emergency stop pressed). For example, in Volvo loaders, the PLC will block the Start signal if the cab door is open.

-

Preheat Controller: Exclusive to diesel machines, the switch activates the controller, which manages glow plug power and preheat duration based on temperature.

-

Fuse Box & Wiring Harness: Links to a heavy-duty fuse box (resistant to vibration) to protect circuits from overloads. Wiring harnesses use sealed, silver-plated connectors for corrosion resistance—essential for wet or salty job sites, as seen in Komatsu and Volvo marine construction equipment.

Frequently Asked Questions (FAQ)

Q1. Are ignition switch part numbers interchangeable across brands?

No. Each manufacturer designs ignition switches to match specific electrical architectures and safety systems. Always verify part numbers by machine model and serial number.

Q2. How can I tell if the ignition switch or preheat system is faulty?

If the preheat indicator functions normally but the engine does not crank, the ignition switch or starter circuit may be at fault. If the preheat light behaves abnormally, the issue likely lies with glow plugs or sensors.

Q3. Can mechanical ignition switches be upgraded to electronic versions?

Possible, but not always cost-effective. Electronic switches require ECU integration and additional wiring modifications.

Q4. How often should ignition switches be inspected?

Every 500 operating hours is recommended, or more frequently in harsh environments such as mining or marine construction sites.

Q5. What happens if the wrong voltage ignition switch is installed?

Using an incorrect voltage rating (12V vs 24V) can cause immediate failure and damage to electrical systems. Always match the machine’s specifications.

Final Thoughts on Heavy Equipment Ignition Switches

Construction equipment ignition switches are engineered to operate reliably under extreme conditions while coordinating safety, power distribution, and engine startup. Understanding how they work helps operators reduce downtime, technicians diagnose issues faster, and fleet managers extend equipment lifespan.

If you are sourcing OEM-compatible ignition switches for John Deere, JCB, Volvo, CAT, Komatsu, Case, or other heavy machinery, choosing high-quality, correctly matched components ensures safe operation and long-term reliability.