At present, pressure gauges are widely used in almost all industrial processes and scientific research fields, such as heat pipe network, oil and gas transmission, water supply and gas system, vehicle maintenance and repair shop and other fields.

Especially in the process of industrial process control and technical measurement, the mechanical pressure gauges have been more and more widely used because of the high mechanical strength and production convenience of the elastic sensitive elements.

Today, SINOCMP has sorted out the basic knowledge of pressure gauges, which I hope will help you to understand.

1.The concept of pressure in pressure gauges

The concept of pressure, in fact, refers to the physical pressure, that is, the amount of pressure per unit area.

Absolute pressure: The pressure higher than zero of absolute pressure, based on zero of absolute pressure.

Positive pressure: The pressure higher than atmospheric pressure, based on atmospheric pressure.

Negative pressure (vacuum) : Pressure lower than atmospheric pressure, based on atmospheric pressure.

Differential pressure: The difference between two pressures.

Gauge pressure: Pressure greater than or less than atmospheric pressure as a reference.

Pressure gauge: An instrument used for measuring less than or greater than atmospheric pressure as a reference.

2.Pressure gauge

In the process of industrial process control and technical measurement, the mechanical pressure gauge has been more and more widely used because of its high mechanical strength and convenient production.

The elastic sensitive element in the mechanical pressure gauge produces elastic deformation with the change of pressure.Mechanical pressure gauges are made of spring tube (Bourdon tube), diaphragm, capsule and bellows and other sensitive elements and are classified accordingly.The pressure measured is generally regarded as relative pressure.Generally, the relative point is selected as atmospheric pressure.The elastic deformation of the elastic element under the action of medium pressure is amplified by the gauge's gear drive, and the gauge will show a relative value (high or low) to atmospheric pressure.The pressure values within the measured range are shown by the pointer, and the indicating range of the dial is usually made to 270 degrees.

3.Classification of pressure gauges

Pressure gauge according to its measurement accuracy, can be divided into precision pressure gauge, general pressure gauge.The precision pressure gauges are of class 0.1, class 0.16, class 0.25, class 0.4;Normal pressure gauges are rated for accuracy of 1.0, 1.6, 2.5 and 4.0 respectively.Pressure gauge according to its indicator pressure reference is different, divided into general pressure gauge, absolute pressure gauge, differential pressure gauge.General pressure gauges with atmospheric pressure as a reference;Absolute pressure gauge is based on absolute pressure zero;The differential pressure gauge measures the difference between the two measured pressures.According to its measuring range, the pressure gauge is divided into vacuum gauge, pressure vacuum gauge, micro pressure gauge, low pressure gauge, medium pressure gauge and high pressure gauge.Vacuum gauge is used to measure the pressure value less than atmospheric pressure.The pressure vacuum gauge is used to measure the pressure value less than or greater than atmospheric pressure.The micrometer is used to measure pressure values less than 60,000 Pa;The low-pressure meter is used to measure the pressure value of 0~6MPa.The medium pressure gauge is used to measure the pressure value of 10~60MPa.The high pressure meter is used to measure the pressure value above 100MPa.The case of the seismic pressure gauge is made of a fully sealed structure, and the damping oil is filled in the case. Due to its damping effect, it can be used to measure the vibration in the working environment or the fluctuating pressure (load) of the medium.The pressure gauge with electric contact control switch can realize the function of sending alarm or controlling.Pressure gauges with remote transmission mechanisms can provide electrical signals (such as resistance signals or standard DC current signals) that are needed in industrial engineering.Diaphragm table used by the isolator (chemical seal) through the isolation diaphragm, the measured medium and the instrument isolated, in order to measure the strong corrosion, high temperature, easy to crystallize the medium pressure.The elastic element of the pressure gauge The elastic sensitive element in the mechanical pressure gauge produces elastic deformation with the change of pressure.Mechanical pressure gauges use spring tubes (Bourdon tubes), diaphragm, diaphragm and bellows and other sensitive elements and according to this classification.The sensing element is usually made of copper alloy, stainless steel or special materials.The spring tube (Bourdon tube) is divided into C type tube, coil spring tube, spiral tube and other types.In general, the blank tube of cold hardening material has high plasticity in annealed state, and high elasticity and strength can be obtained after cold hardening and qualitative treatment by pressure processing.Under the action of the pressure in the inner chamber of the spring tube, the pressure can be easily converted into the elastic displacement of the free end of the spring tube by using its elastic characteristics.The measuring range of the spring tube is generally 0.1~ 250MPa.The diaphragm sensing element is a circular diaphragm with waves, the diaphragm itself located between two flanges, or welded to the flange or its edge sandwiched between the two flanges.One side of the diaphragm is subjected to pressure from the measuring medium.The tiny bending deformation thus produced by the diaphragm can be used to indirectly measure the pressure of the medium.The pressure is indicated by the pointer.The transmissible force of the diaphragm is greater than that of the Bourdon tube.As the surrounding edge of the diaphragm is fixed, the vibration resistance of the diaphragm is better.Diaphragm pressure gauges provide very high overpressure protection (e.g. diaphragm attached to the upper flange).A protective coating may also be added to the diaphragm to improve the corrosion resistance.Open flange, flushing, opening and other measures can be used to measure the diaphragm pressure gauge viscosity is very large, unclean and crystalline medium. The pressure measuring range of diaphragm pressure gauges is 1600Pa ~ 2.5 MPa.

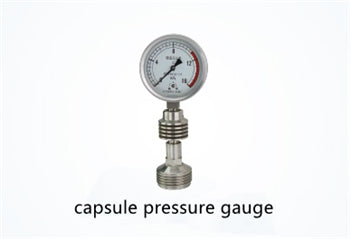

The membrane box sensing element consists of two diaphragms with a circular wave section clasped together.The pressure of the measuring medium ACTS on the inside of the capsule cavity, and the resulting deformation can be used to indirectly measure the pressure of the medium.The size of the pressure value is shown by the pointer.Pressure gauges with capsule element are generally used to measure the micro pressure of gases and have a certain degree of overpressure protection.Several capsule sensing elements stacked together produce a large transfer force to measure extremely small pressures.Pressure gauges with capsule type range from 250 to 60000Pa.

Note: SINOCMP service in construction machinery Parts for around 10 years in China. We cooperate with professional factory with boundary of electric parts, hydraulic parts, and engine parts. Based on the chinese technical and on technology and service advantages, we expand our business to South Asia, South-east Asia, Europe, North America, South America, etc. SINOCMP is your best choice.

1 comment

I like the tip that you gave that pressure gauges are always used for technical measurement and process control. Last night, my cousin told me that he and his business partner were looking for a pressure gauge manufacturer that could provide a safety pattern, and he asked if I had any idea. I’m glad for this informative article, I’ll tell him that they can consult a trusted pressure gauge company for more information about their services. https://www.directmaterial.com/gauges-industrial-thermometers/pressure-gauges