Overview guide to LBZ injectors

LBZ Duramax injectors are a critical component of the 6.6L Duramax engine, known for their robust performance and durability. Introduced in the 2006 to 2007 model year trucks, LBZ injectors represent an upgrade over their predecessors, offering improved efficiency and power delivery. In this guide, we will delve into the features, compatibility, purchasing considerations, and maintenance tips for LBZ Duramax injectors.

Features of LBZ Injectors

LBZ injectors are designed with precision to meet the demanding requirements of the 6.6L Duramax engine. These injectors are equipped with:

- Enhanced fuel atomization for improved combustion efficiency.

- Advanced nozzle design for optimal fuel delivery and power output.

- Injector cups, metal sleeves that provide a seal for the injectors and channel fuel into the combustion chamber.

- Compatibility with LBZ Duramax engines in 2006 to 2007 model year trucks.

Purchasing Considerations

When considering purchasing LBZ injectors, there are several factors to keep in mind:

- Compatibility: Ensure the injectors are compatible with your specific LBZ Duramax engine model and year.

- Quality: Opt for reputable brands or genuine OEM injectors to ensure reliability and performance.

- Remanufactured vs. New: Decide between remanufactured or new injectors based on budget and preferences. Remanufactured injectors can offer cost savings without compromising quality.

- Injector Cups: Consider replacing injector cups when replacing LBZ injectors to prevent leaks and ensure proper sealing.

Are LLY and LBZ Injectors the Same?

The LLY and LBZ injectors are not the same; they have several differences in design and performance. Let's compare the two to understand their distinctions:

1. Engine Compatibility:

- LLY: Used in 2004.5 to 2005 model year trucks.

- LBZ: Used in 2006 to 2007 model year trucks.

2. Injector Design:

-

LLY Injectors:

- Known for a smaller nozzle size compared to LBZ injectors.

- The nozzle design is older and less efficient.

- May have issues with cracking under high pressure.

-

LBZ Injectors:

- Upgraded design with larger nozzles for improved fuel atomization.

- Enhanced nozzle design allows for better fuel delivery and power output.

- Improved efficiency and performance over LLY injectors.

3. Performance:

-

LLY Injectors:

- Older design with limitations on power and efficiency.

- Known for injector failures due to cracking or wear.

- May lead to rough idling, misfires, and reduced performance.

-

LBZ Injectors:

- Upgraded design offers better performance and efficiency.

- Improved fuel atomization for cleaner combustion.

- Less prone to failures compared to LLY injectors.

4. Injector Cups:

-

LLY Injectors:

- Some models may have issues with injector cup failures.

- Injector cups are prone to wear and may cause leaks.

-

LBZ Injectors:

- Equipped with injector cups for improved sealing and fuel delivery.

- Injector cups are designed for durability and longevity.

5. Durability:

-

LLY Injectors:

- Known for issues with durability, especially under high pressure.

- Common complaints of injector failures and replacements.

-

LBZ Injectors:

- Upgraded materials and design for improved durability.

- Less prone to failures and longer lifespan compared to LLY injectors.

6. Compatibility with Tuning:

-

LLY Injectors:

- May require upgraded injectors for higher performance tuning.

- Limited compatibility with aggressive tuning due to smaller nozzle size.

-

LBZ Injectors:

- Better compatibility with performance tuning.

- Larger nozzles allow for more fuel delivery and power gains.

Conclusion:

In summary, the LLY and LBZ injectors differ significantly in design, performance, and durability. The LBZ injectors, used in 2006 to 2007 Duramax trucks, represent an upgrade over the older LLY injectors in terms of efficiency, power output, and reliability. LBZ injectors feature larger nozzles, improved fuel atomization, and enhanced durability with injector cups. They are less prone to failures and are better suited for performance tuning compared to LLY injectors. If considering an upgrade or replacement, opting for LBZ injectors can provide improved engine performance and longevity.

How Do I Know If My LBZ Injectors Are Bad?

LBZ Duramax injectors are crucial components of the 6.6L Duramax engine, responsible for delivering fuel to the combustion chamber with precision. Over time, LBZ injectors can develop issues that affect engine performance. Here are some signs to watch for that may indicate your LBZ injectors are bad:

1. Rough Idle or Misfires

- One of the most common signs of bad injectors is a rough idle or frequent misfires. You may notice the engine shaking or vibrating more than usual, especially at idle.

2. Reduced Engine Performance

- Bad LBZ injectors can lead to a noticeable decrease in engine performance. This can manifest as sluggish acceleration, reduced power output, or a general lack of responsiveness when pressing the accelerator pedal.

3. Excessive Smoke from the Exhaust

- If you observe thick, black smoke coming from the exhaust, it could be a sign of faulty LBZ injectors. The excess fuel not properly atomized by the injectors can result in unburned fuel being expelled as smoke.

4. Increased Fuel Consumption

- Malfunctioning LBZ injectors may cause the engine to consume more fuel than usual. You may find yourself refueling more frequently, even with normal driving habits.

5. Engine Knocking or Ticking Noises

- Damaged LBZ injectors can lead to engine knocking or ticking noises, especially under load or acceleration. These noises may indicate fuel is not being properly delivered and burned in the combustion chamber.

6. Check Engine Light (CEL) with Injector-Related Fault Codes

- When LBZ injectors begin to fail, the vehicle's onboard computer (ECU) may detect the issue and trigger the check engine light. Use an OBD-II scanner to retrieve any injector-related fault codes, such as P0201 to P0212 (injector circuit malfunction).

7. Difficulty Starting or Stalling

- Faulty LBZ injectors can cause starting issues, such as extended cranking before the engine starts. Additionally, the engine may stall or shut off unexpectedly while driving, particularly at low speeds or idle.

8. Fuel Odor

- If you notice a strong smell of fuel inside or outside the vehicle, it could be a sign of leaking injectors. Leaking LBZ injectors can allow excess fuel to escape, creating a noticeable odor.

9. Loss of Engine Power Under Load

- When LBZ injectors are failing, you may experience a loss of engine power when towing or carrying heavy loads. The engine may struggle to maintain speed or climb hills.

What to Do If You Suspect Bad LBZ Injectors

If you notice any of the above signs or suspect your LBZ injectors are bad, it's essential to address the issue promptly to prevent further damage to the engine. Here are steps to take:

-

Diagnostic Scan: Use an OBD-II scanner to retrieve any stored fault codes from the vehicle's computer. Injector-related codes can pinpoint which injectors may be failing.

-

Visual Inspection: Check for any signs of fuel leaks around the injectors or a strong fuel odor. Inspect the engine bay for wet spots or stains.

-

Professional Inspection: If you're uncertain about the condition of your LBZ injectors, it's best to have a professional mechanic perform a thorough inspection. They can conduct a fuel system pressure test and injector balance test to diagnose the issue accurately.

-

Replace or Rebuild: If your LBZ injectors are indeed faulty, you have the option to replace them with new or remanufactured injectors. Rebuilding injectors is also a viable option, especially if you prefer to retain the original components.

Conclusion

Being aware of the signs of bad LBZ injectors can help you detect issues early and prevent potential engine damage. If you notice any of these symptoms or suspect injector problems, it's crucial to address them promptly. Consult with a qualified mechanic for proper diagnosis and repair to ensure your LBZ Duramax engine continues to run smoothly and efficiently.

How Long Do LBZ Injectors Last: OEM, High-Quality Aftermarket, and Remanufactured Options

LBZ Duramax injectors are vital components of the 6.6L Duramax engine, responsible for delivering fuel with precision. The lifespan of LBZ injectors can vary based on factors such as driving conditions, maintenance practices, and fuel quality. Here's a breakdown of the expected lifespan for different types of LBZ injectors:

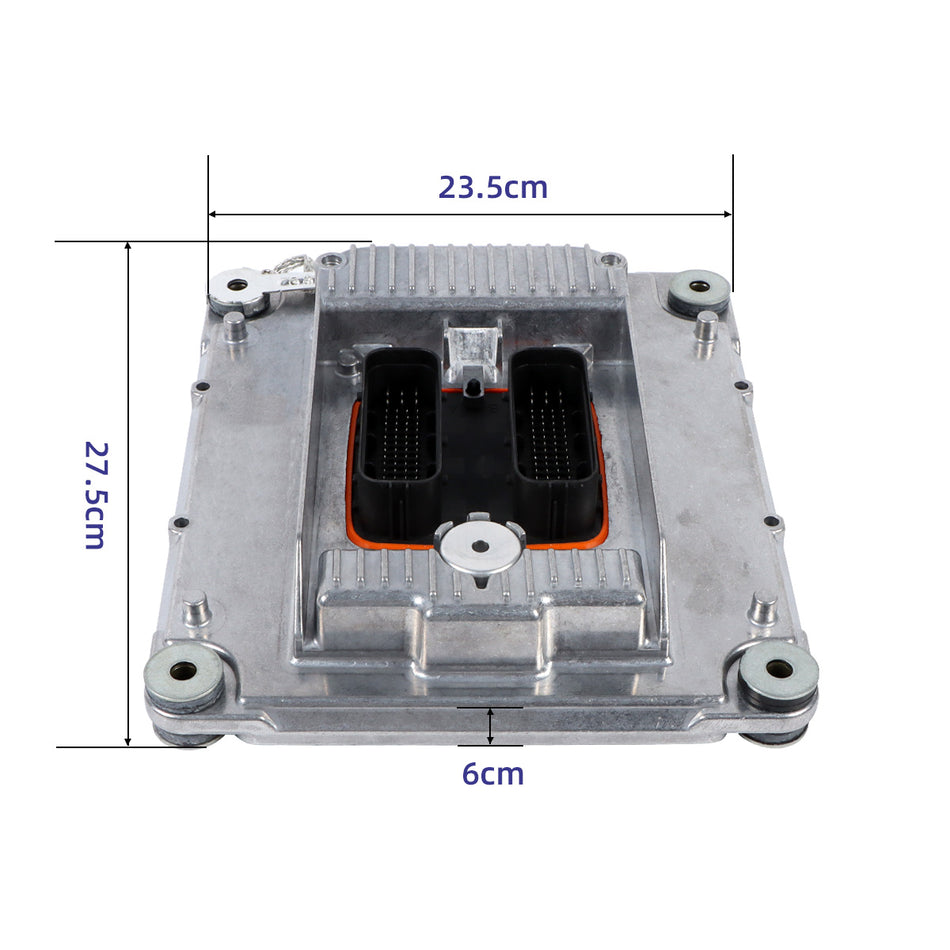

1. OEM LBZ Injectors

- Original Equipment Manufacturer (OEM) LBZ injectors are manufactured by the same company that produced the injectors for the vehicle when it was new. These injectors are built to meet the exact specifications and quality standards of the manufacturer.

- Lifespan: OEM LBZ injectors are designed to be highly durable and can last anywhere from 100,000 to 200,000 miles under normal driving conditions.

- Quality: OEM injectors offer the highest level of quality and compatibility with the vehicle. They are built to the manufacturer's strict standards and specifications, ensuring optimal performance and reliability.

- Cost: OEM injectors are typically the most expensive option due to their high-quality construction and brand reputation.

2. High-Quality Aftermarket LBZ Injectors

- High-quality aftermarket LBZ injectors are produced by reputable manufacturers who specialize in diesel engine components. These injectors are designed to meet or exceed OEM specifications.

- Lifespan: High-quality aftermarket LBZ injectors can last a similar length of time as OEM injectors, ranging from 100,000 to 200,000 miles.

- Quality: These injectors are engineered with precision and undergo rigorous testing to ensure performance and reliability. They often feature improvements over OEM designs to enhance fuel delivery and efficiency.

- Cost: Aftermarket LBZ injectors are generally more affordable than OEM injectors while offering comparable quality. They provide a cost-effective alternative without sacrificing performance.

3. Remanufactured LBZ Injectors

- Remanufactured LBZ injectors are OEM injectors that have been disassembled, inspected, and rebuilt to meet or exceed OEM specifications. The process involves replacing worn components, such as nozzles, seals, and o-rings.

- Lifespan: Remanufactured LBZ injectors can last as long as OEM injectors, typically between 100,000 to 200,000 miles.

- Quality: Reputable remanufacturers follow strict procedures to ensure the injectors are restored to like-new condition. They are tested extensively to meet performance and durability standards.

- Cost: Remanufactured LBZ injectors are generally more affordable than OEM injectors and offer excellent value for money. They provide a reliable option for those seeking quality injectors at a lower cost.

Factors Affecting Injector Lifespan

- Driving Conditions: Harsh driving conditions, such as towing heavy loads or frequent stop-and-go traffic, can put more stress on injectors and shorten their lifespan.

- Maintenance: Regular maintenance, including fuel filter changes, can help prolong the lifespan of LBZ injectors by ensuring clean fuel and proper engine operation.

- Fuel Quality: Poor-quality or contaminated fuel can lead to injector clogging or damage, reducing their lifespan. Using high-quality diesel fuel and additives can help maintain injector health.

Conclusion

In conclusion, the lifespan of LBZ injectors can vary depending on the type and quality. OEM and high-quality aftermarket LBZ injectors can last between 100,000 to 200,000 miles, offering reliability and performance. Remanufactured LBZ injectors provide a cost-effective option with comparable lifespan and quality to OEM injectors. Regardless of the type chosen, proper maintenance and care are essential to maximize the lifespan of LBZ injectors and ensure optimal engine performance.

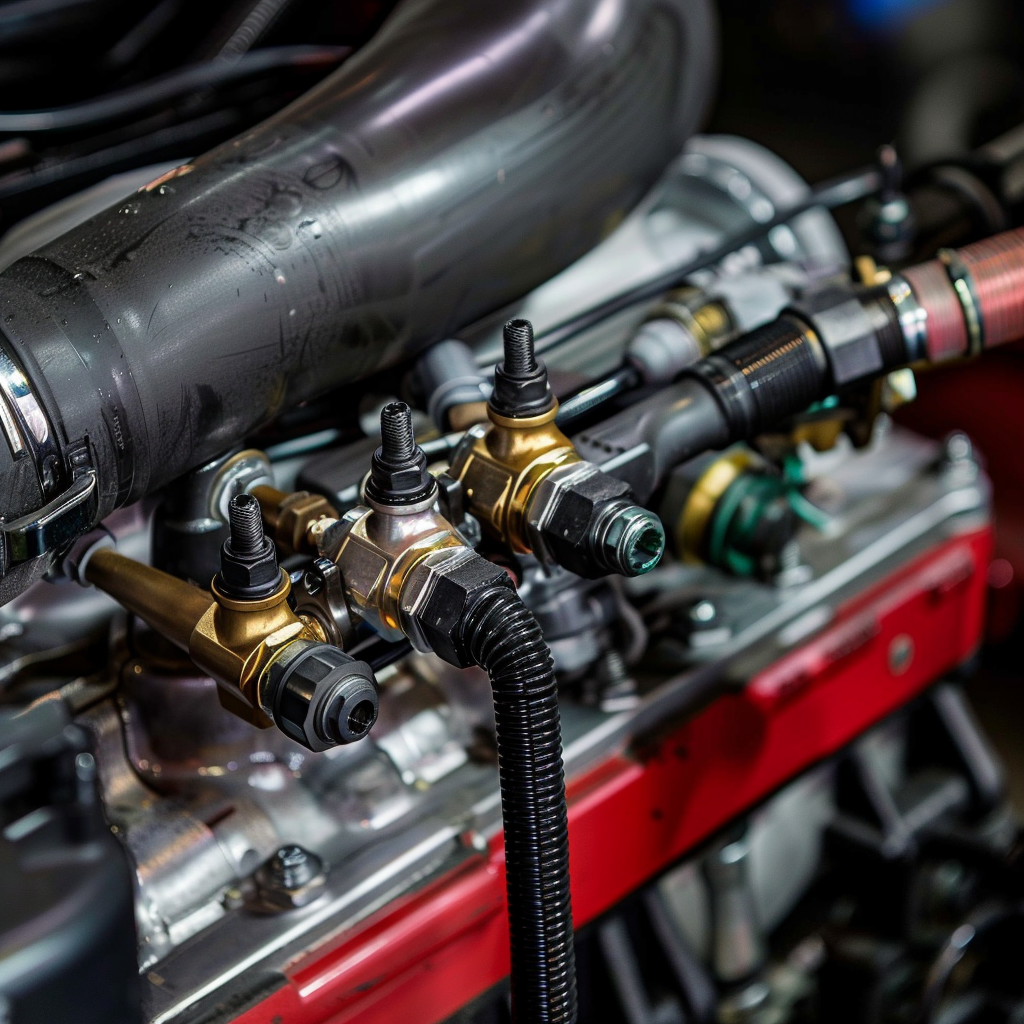

How to Replace and Change Injectors on 6.6 LBZ Duramax

Replacing injectors on a 6.6 LBZ Duramax engine is a detailed process that requires careful attention to ensure proper installation. Here's a step-by-step guide on how to replace and change injectors on a 6.6 LBZ Duramax engine:

Tools and Materials Needed:

- LBZ injectors

- New injector seals

- Torque wrench

- Socket set

- Flathead screwdriver

- Clean rags

- Fuel line disconnect tool

- Coolant drain pan

Steps:

1. Prepare the Vehicle

- Park the vehicle on a flat surface and allow the engine to cool completely.

- Disconnect the negative battery terminal to prevent accidental electrical issues.

2. Drain the Coolant

- Place a coolant drain pan beneath the radiator drain valve.

- Open the radiator drain valve and allow the coolant to drain completely.

- Close the drain valve once the coolant has drained.

3. Remove Valve Covers

- Locate the valve covers on the engine and remove them using a socket set.

- Set the valve covers aside in a safe place.

4. Remove High-Pressure Fuel Lines

- Use a fuel line disconnect tool to disconnect the high-pressure fuel lines from the injectors.

- Label each fuel line to ensure correct reinstallation later.

5. Disconnect Electrical Connectors

- Locate the electrical connectors on each injector and disconnect them.

- Gently squeeze the tabs on the connectors and pull them off.

6. Remove Injector Hold-Down Bolts

- Locate the injector hold-down bolts on each injector.

- Use a socket set to loosen and remove the hold-down bolts.

- Keep track of the bolts and washers for each injector.

7. Remove the Injectors

- Carefully lift each injector out of its bore using a twisting motion.

- Be gentle to avoid damaging the injector or the bore.

8. Install New Injectors

- Apply a small amount of clean engine oil to the o-rings on the new injectors.

- Carefully insert each new injector into its bore, ensuring proper alignment.

- Install the injector hold-down bolts and washers, and torque them to the manufacturer's specifications.

9. Reconnect Electrical Connectors and Fuel Lines

- Reconnect the electrical connectors to each injector.

- Reconnect the high-pressure fuel lines to the injectors using the fuel line disconnect tool.

- Ensure each connection is secure.

10. Reinstall Valve Covers

- Place the valve covers back onto the engine and secure them with the bolts.

- Torque the valve cover bolts to the manufacturer's specifications.

11. Refill Coolant

- Refill the cooling system with the appropriate coolant mixture.

- Bleed any air from the cooling system according to the manufacturer's instructions.

12. Test Run

- Start the engine and allow it to idle for a few minutes.

- Check for any leaks around the injector area.

- Test drive the vehicle to ensure proper operation.

Conclusion

Replacing injectors on a 6.6 LBZ Duramax engine is a challenging but manageable task with the right tools and knowledge. Following these steps carefully will help ensure a successful injector replacement, restoring your engine's performance and efficiency. If you're unsure about performing this task yourself, it's always recommended to seek assistance from a professional mechanic.

Can You Rebuild LBZ Injectors?

LBZ Duramax injectors, critical for optimal engine performance, can sometimes develop issues over time. Rebuilding LBZ injectors is a viable option, especially for those seeking cost-effective solutions without compromising quality. Here's what you need to know:

Rebuilding LBZ Injectors:

LBZ injectors can be rebuilt by skilled professionals or reputable injector rebuilders. The process involves:

-

Disassembly: LBZ injectors are carefully disassembled, and each component is inspected for wear, damage, or buildup.

-

Cleaning and Testing: Parts are thoroughly cleaned using specialized equipment to remove debris and buildup. Each component, including nozzles and valves, is rigorously tested for proper function.

-

Replacement of Components: Worn or damaged parts such as nozzles, seals, o-rings, and springs are replaced with high-quality components. This ensures optimal performance and longevity.

-

Reassembly: After replacement parts are installed, LBZ injectors are carefully reassembled following manufacturer specifications to maintain precision and reliability.

-

Final Testing: Rebuilt LBZ injectors undergo comprehensive testing to ensure proper fuel delivery, atomization, and performance. This includes testing for leaks, spray patterns, and flow rates.

Benefits of Rebuilt LBZ Injectors:

-

Cost-Effective: Rebuilding LBZ injectors is often more affordable than purchasing new ones.

-

Quality Control: Reputable rebuilders adhere to strict quality control standards, ensuring reliable performance.

-

Environmentally Friendly: Rebuilding LBZ injectors reduces waste by extending the lifespan of existing components.

-

Warranty Options: Many rebuilt LBZ injectors come with warranties, providing peace of mind to customers.

Aftermarket vs. OEM vs. Remanufactured Injectors:

When considering LBZ injectors, it's essential to understand the different types:

-

Aftermarket Injectors: These are produced by third-party manufacturers and are designed to meet or exceed OEM specifications. Aftermarket LBZ injectors from reputable brands offer a balance of quality and affordability.

-

OEM (Original Equipment Manufacturer) Injectors: These are produced by the vehicle's original manufacturer, in this case, GM. They are built to exact specifications and are generally more expensive than aftermarket options.

-

Remanufactured Injectors: These are OEM injectors that have been disassembled, cleaned, inspected, and rebuilt to meet or exceed OEM standards. Remanufactured LBZ injectors offer OEM quality at a lower price point.

Our Offerings:

We primarily offer high-quality aftermarket LBZ injectors, known for their reliability and performance. These injectors are designed to fit and function like OEM parts but at a more competitive price point. However, if customers require remanufactured LBZ injectors, we can source them through our reputable channels.

Conclusion:

In summary, LBZ Duramax injectors can be rebuilt by skilled professionals, offering a cost-effective solution for customers seeking quality replacements. Rebuilding involves thorough cleaning, testing, and replacement of worn parts to ensure optimal performance. Our offerings include high-quality aftermarket LBZ injectors, with the option to source remanufactured injectors as needed. Customers can expect reliable performance and affordability with our LBZ injector options.

Understanding LBZ Duramax injectors is crucial for maintaining optimal performance and reliability of your 6.6L Duramax engine. Whether you're dealing with signs of bad injectors, considering replacement options, or exploring the possibility of rebuilding, this comprehensive guide has provided valuable insights.

From identifying symptoms of bad LBZ injectors to discussing the benefits of aftermarket and remanufactured options, we've covered it all. Remember, regular maintenance and timely replacement of injectors are essential for the longevity of your engine.

At SINOCMP, we offer a range of high-quality LBZ injectors, primarily focusing on aftermarket options known for their reliability and affordability. For those needing remanufactured injectors, we can source them through reputable channels. Trust [Your Company Name] for your LBZ injector needs, ensuring your Duramax engine continues to perform at its best.