Are you looking to get the best performance and reliability out of your diesel engine? Cummins fuel injectors play a critical role in delivering precise fuel to your engine, directly impacting power output, fuel efficiency, emissions, and long-term durability.

In this complete guide, we’ll break down Cummins injector types by engine model and year, explain how injector technology supports emissions compliance, explore performance upgrade options, and share practical maintenance tips to help you choose the right injector for your Cummins-powered vehicle.

Choosing the right Cummins fuel injector isn’t just about power—it’s about reliability, efficiency, and protecting your engine investment.

What do Cummins fuel injectors do?

Cummins fuel injectors are responsible for atomizing diesel fuel and delivering it into the combustion chamber at extremely high pressure. Proper injector performance ensures:

- Efficient combustion

- Optimal horsepower and torque

- Lower exhaust gas temperatures (EGT)

- Reduced emissions and smoke

- Longer engine life

Worn or mismatched injectors can lead to rough idling, poor fuel economy, excessive smoke, or even engine damage—making correct selection and maintenance essential.

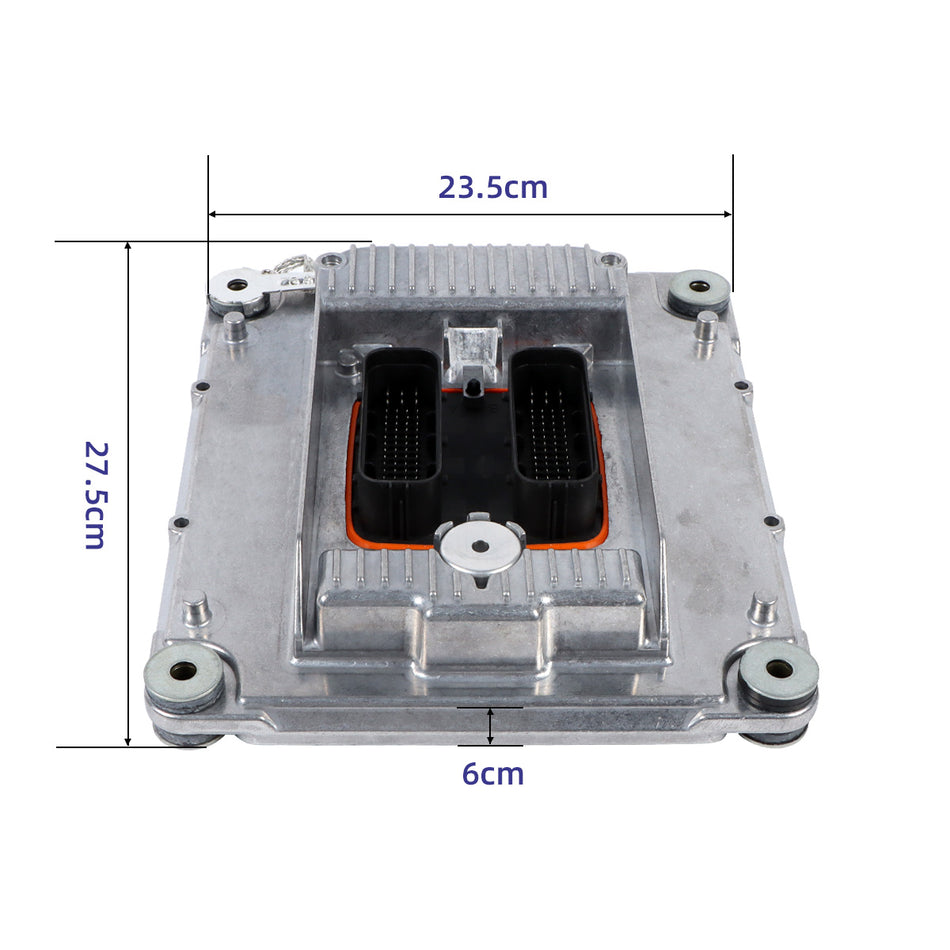

SINOCMP Top-selling Fuel Injector for Cummins

Fuel Injector with Tube 2872331 5579409PX 5579409 for Cummins ISL 8.9L Diesel Engine

Types of Cummins Fuel Injectors by Engine Model

Cummins injectors are engineered specifically for different engine families, fuel systems, and emission requirements. Below are the most common injector categories.

5.9L Cummins Injectors (12V & 24V)

The 5.9L Cummins engine is one of the most widely used diesel platforms, spanning both mechanical and electronic injection systems:

- 12 Valve (1989–1998): Mechanical injectors paired with VE or P-pumps, commonly upgraded via nozzle size and flow rate.

-

24 Valve (1998.5–2006): Electronically controlled injectors offering improved fuel precision and efficiency.

Common applications include:

2003 5.9 Cummins injectors

2005 Cummins injectors

2006 5.9 Cummins injectors

These injectors are widely available in stock and performance flow options for daily driving, towing, or high-horsepower builds.

6.7L Cummins Fuel Injectors (2007.5+)

The 6.7 Cummins introduced advanced common-rail injection to meet stricter emission standards.

Key features:

-

Higher injection pressures

-

Multiple injection events per cycle

-

Improved fuel atomization

6.7 Cummins fuel injectors are commonly used in:

-

2007.5–2010 models (early emissions systems)

-

2011+ models with refined emissions control

These injectors are ideal for drivers prioritizing emissions compliance, smooth operation, and reliable towing performance, with aftermarket options available for power upgrades.

Cummins N14 & ISX Injectors (Heavy-Duty Engines)

For commercial and industrial use, Cummins N14 injectors and ISX injectors are built for extreme durability and consistent fuel delivery under heavy loads.

- Designed for long-haul and industrial applications

- High fuel flow with precise control

- Emphasis on longevity and reliability

These injectors focus on consistency and longevity rather than peak horsepower.

Cummins Injector Compatibility by Year

Injector design and control strategy can vary significantly by model year.

-

Early models (pre-2003) relied heavily on mechanical fueling

-

2003–2006 marked the transition to electronically controlled injectors

-

2007.5+ introduced high-pressure common rail systems with advanced emissions control

👉 Always confirm engine year, part number, and fuel system type before purchasing injectors to ensure exact compatibility.

Emission Control & Injector Technology

As diesel emission regulations tightened, Cummins continuously refined injector technology to reduce NOx and particulate matter without sacrificing power.

Modern Cummins injectors utilize pilot injection, multiple injection pulses, and optimized nozzle geometry to ensure cleaner combustion and lower emissions.

Performance Upgrades for Cummins Fuel Injectors

Upgrading injectors is a popular way to increase horsepower and torque, especially when paired with turbo or fuel system upgrades.

- Stock or mild upgrades for daily driving and light towing

- +30% flow injectors for heavy towing

- High-flow injectors for 500+ HP performance builds

Important: Oversized injectors without proper tuning may cause excessive smoke, high EGTs, and reduced reliability.

Cummins Injector Maintenance & Replacement Tips

Routine Maintenance

To extend injector life:

- Use high-quality diesel fuel

- Replace fuel filters regularly

- Use injector cleaner periodically

- Inspect for leaks or abnormal noise

When to Replace Injectors

Common warning signs include:

- Hard starts or rough idle

- Loss of power

- Increased fuel consumption

- Excessive black or white smoke

Older injectors—such as early 5.9 Cummins injectors—may lose efficiency after extended mileage and should be tested or replaced as needed.

How to Choose the Right Cummins Fuel Injector

Selecting the correct injector depends on:

-

Engine model and year

-

Fuel Injector Part Number

Looking for the right Cummins injector?

Choosing the correct injector ensures reliable performance and protects your engine investment. Explore exact-fit Cummins fuel injectors by engine model, or contact diesel parts specialists for compatibility confirmation before ordering.

Conclusion: Get the Most Out of Your Cummins Injectors

Understanding Cummins fuel injectors—from 5.9 and 6.7 models to heavy-duty N14 injectors—helps you make informed decisions about maintenance, upgrades, and replacements.

With proper selection and care, your Cummins engine can deliver reliable power, efficiency, and longevity for years to come.

👉 Explore SINOCMP Cummins fuel injector