Welcome to our comprehensive guide on maintaining injectors for the 6.7 Cummins diesel engine. This engine is renowned for its power and durability, but like any complex machinery, proper maintenance is key to longevity and performance. In this guide, we'll cover everything you need to know about the injectors in the 6.7 Cummins, including their function, quantity, programming needs, removal and cleaning procedures, lifespan, and common maintenance issues.

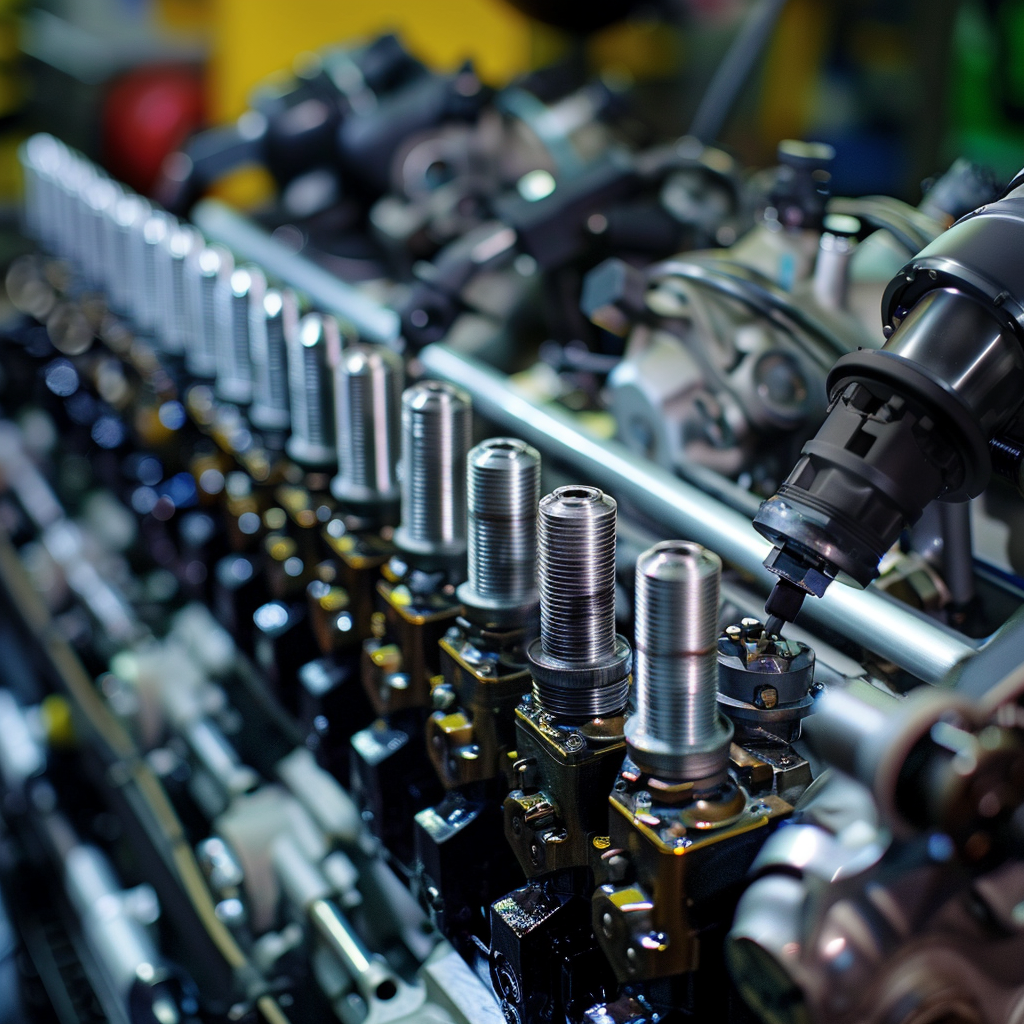

Overview of 6.7 Cummins Diesel Engine Injectors

The 6.7 Cummins diesel engine injectors are a critical component found in a variety of vehicles, ranging from heavy-duty trucks to recreational vehicles (RVs) and even some commercial equipment. Let's delve deeper into the specifics of these injectors, including their features, part numbers, categories (such as remanufactured, OEM, aftermarket), and the original manufacturers (such as Bosch, Cummins, etc.). if you want know more about 6.7 Cummins Diesel Engine Injectors, click here.

How Many Injectors are in a 6.7 Cummins and Programming Requirements

The 6.7 Cummins diesel engine, known for its power and efficiency, utilizes a specific number of injectors to ensure optimal performance. Additionally, understanding whether these injectors require programming is crucial for maintenance and replacement considerations. Let's delve into these aspects

How Many Injectors are in a 6.7 Cummins?

The 6.7 Cummins diesel engine is equipped with six injectors. Each cylinder in the inline-six engine has its own injector. This specific configuration ensures precise fuel delivery to each cylinder, optimizing performance, fuel efficiency, and emissions control.

Reasons for Six Injectors:-

Engine Configuration: The 6.7 Cummins diesel engine follows an inline-six design. This means there are six cylinders arranged in a straight line. To ensure each cylinder receives adequate fuel, there is one injector per cylinder.

-

Power and Torque Demands: This engine is commonly used in heavy-duty trucks, commercial vehicles, and RVs, where high power and torque are essential. Six injectors provide the necessary fuel supply to meet these demands, especially under heavy loads and high-speed driving conditions.

-

High-Pressure Common Rail System: The 6.7 Cummins engine utilizes a high-pressure common rail fuel system. This system requires precise control over fuel delivery to each cylinder. Having six injectors allows for efficient and controlled fuel injection at high pressures.

-

Fuel Economy: Along with providing ample power, the 6.7 Cummins engine aims for fuel efficiency. The design with six injectors ensures that fuel is delivered efficiently, avoiding wastage and optimizing fuel economy.

-

Emissions Compliance: Meeting stringent emission standards is crucial for modern diesel engines. The 6.7 Cummins engine with six injectors can achieve cleaner combustion, reducing harmful emissions.

-

Balanced Performance: Each cylinder receiving fuel from its injector ensures balanced and consistent performance across all cylinders.

-

Efficient Combustion: The six injectors enable precise fuel injection, promoting efficient combustion for improved fuel economy and power output.

-

Reliability: With multiple injectors, the engine can continue running even if one injector fails, minimizing the impact of a malfunction.

The choice of six injectors in the 6.7 Cummins diesel engine is based on its inline-six cylinder configuration, power demands, fuel efficiency goals, and emissions compliance requirements. This design ensures optimal performance, efficiency, and reliability for a range of heavy-duty applications.

This explanation provides insight into why the 6.7 Cummins engine requires six injectors, highlighting its design principles and advantages. If you have further questions or require more information, feel free to reach out

Do 6.7 Cummins Injectors Need to be Programmed?

When it comes to the 6.7 Cummins diesel engine, one common question is whether aftermarket or remanufactured injectors require programming. In our case, focusing on aftermarket and remanufactured products, it's important to understand that these types of injectors do not typically need programming. Let's delve into why this is the case and how these injectors are adjusted during production and testing.

Programming Requirement for Original Equipment Manufacturer (OEM) Injectors

Before we dive into aftermarket and remanufactured injectors, it's important to note that OEM injectors, such as those from Cummins or Bosch, often require programming. This programming involves adjusting parameters such as fuel delivery rate, fuel volume, and other relevant factors to ensure proper engine operation.

Aftermarket and Remanufactured Injectors: No Programming Needed

-

Adjustments During Production:

- Aftermarket and remanufactured injectors go through a meticulous production process where key parameters are set and adjusted.

- During the manufacturing process, factors like fuel delivery rate, fuel volume, and other performance-related metrics are carefully calibrated.

- This means that when these injectors are installed, they are already set to perform optimally within the 6.7 Cummins engine without the need for additional programming.

-

Testing and Quality Control:

- These injectors are extensively tested before leaving the factory.

- Tests include ensuring proper fuel delivery rates and volumes, as well as other performance criteria.

- Any necessary adjustments are made during this testing phase, ensuring that the injectors are ready for installation without further programming.

-

Installation Considerations:

- When installing aftermarket or remanufactured injectors, it's important to follow proper installation procedures to ensure they are fitted correctly.

- While programming may not be necessary, proper installation techniques such as torque specifications and seal integrity are crucial.

Benefits of No Programming for Aftermarket and Remanufactured Injectors

-

Ease of Installation: Mechanics and technicians appreciate the simplicity of installing injectors that do not require additional programming steps.

-

Cost-Effectiveness: By eliminating the need for programming, aftermarket and remanufactured injectors can be a more cost-effective option for vehicle owners.

-

Reliable Performance: With adjustments made during production and thorough testing, these injectors are designed to deliver reliable performance without the need for post-installation programming.

In conclusion, aftermarket and remanufactured injectors for the 6.7 Cummins diesel engine do not typically require programming. This is due to the meticulous adjustments made during production, comprehensive testing, and focus on key performance metrics. When installing these injectors, following proper installation procedures is crucial for optimal performance.

Understanding this aspect of aftermarket and remanufactured injectors can help vehicle owners and technicians make informed decisions when it comes to maintenance and replacement. If you have any further questions or inquiries about these injectors, feel free to reach out.

How to change injectors on a 6.7 cummins

Changing injectors on a 6.7 Cummins diesel engine requires precision and attention to detail. Here is a general guide on how to change injectors on a 6.7 Cummins:

Tools and Materials Needed:

- New injectors

- Socket wrench set

- Torque wrench

- Fuel line disconnect tool

- Injector puller tool (optional)

- Clean rags

- Safety gloves and goggles

Steps to Change Injectors:

-

Prepare the Vehicle:

- Park the vehicle on a flat, level surface and engage the parking brake.

- Disconnect the negative terminal of the battery to prevent any electrical accidents.

-

Drain the Fuel System:

- Before starting, relieve the fuel system pressure by locating the Schrader valve on the fuel rail and pressing the center pin to release the pressure.

- Place a catch pan under the fuel filter housing to catch any fuel that may spill.

-

Remove the Fuel Lines:

- Use a fuel line disconnect tool to disconnect the fuel lines from the fuel filter housing and each injector.

- Be prepared for some fuel to leak out; have rags ready to catch any spills.

-

Remove the Valve Cover:

- Locate and remove the valve cover(s) to access the injectors.

- The valve cover is typically held in place by several bolts; carefully remove these bolts and lift off the cover.

-

Remove the Injector Lines:

- Each injector has a high-pressure line connecting it to the fuel rail.

- Loosen and remove the nuts securing these lines to the injectors. Be gentle to avoid damaging the lines.

-

Remove the Injectors:

- Using a socket wrench, carefully loosen and remove the bolts holding the injectors in place.

- It's recommended to use an injector puller tool to gently remove the injectors from their bores. If you don't have a puller tool, be very careful not to damage the injector or the bore.

-

Clean the Injector Bores:

- Once the injectors are removed, inspect the injector bores for any debris or buildup.

- Use a clean rag to carefully clean the bores, ensuring they are free of dirt or old gasket material.

-

Install the New Injectors:

- Apply a small amount of clean engine oil to the o-rings of the new injectors to aid in installation.

- Carefully insert the new injectors into their respective bores, making sure they seat properly.

-

Secure the Injectors:

- Carefully tighten the bolts that secure the injectors, following the specific torque specifications for your engine model.

- Reconnect the high-pressure lines to each injector, ensuring they are properly seated and tightened.

-

Reinstall the Valve Cover:

- Place the valve cover(s) back in position and secure them with the bolts.

- Tighten the bolts evenly and to the specified torque.

-

Reconnect Fuel Lines:

- Using the fuel line disconnect tool, reconnect the fuel lines to the injectors and the fuel filter housing.

- Ensure all connections are secure and free of leaks.

-

Prime the Fuel System:

- Reconnect the negative battery terminal.

- Turn the ignition key to the "ON" position for a few seconds to allow the fuel system to pressurize.

- Check for any fuel leaks around the injectors and fuel lines.

-

Test and Verify:

- Start the engine and allow it to idle for a few minutes, checking for smooth operation and any abnormal sounds.

- Take the vehicle for a test drive to ensure proper performance.

It's important to note that this is a general overview of the injector replacement process for a 6.7 Cummins engine. The exact steps and specifications may vary depending on the specific model year and configuration of your vehicle. Always refer to the vehicle's service manual for detailed instructions and torque specifications. If you're not comfortable with this level of mechanical work, it's advisable to seek assistance from a professional mechanic.

Remove and Clean DEF Injector on 6.7 Cummins

The Diesel Exhaust Fluid (DEF) injector plays a crucial role in the emission control system of the 6.7 Cummins engine. Over time, these injectors can become clogged or contaminated, affecting engine performance and emission levels. Here's a detailed guide on how to safely remove and clean the DEF injector.

How to Remove DEF Injector on 6.7 Cummins:

Removing the Diesel Exhaust Fluid (DEF) injector on a 6.7 Cummins engine is a precise process that requires attention to detail. Here's a step-by-step guide on how to safely and effectively remove the DEF injector:

1. Preparation:

- Ensure the engine is cool and turned off before starting any work.

- Use proper safety gear such as gloves and safety glasses for protection.

2. Locate the DEF Injector:

- Depending on the vehicle model and engine layout, locate the DEF injector. It is typically positioned in a specific location within the emissions system, often near the exhaust pipe.

3. Power Off and Depressurize:

- Disconnect power to prevent accidental engine start-up.

- Depressurize the system by opening valves or the vent on the emissions system.

4. Disconnect Wiring and Lines:

- Unplug the electrical connector attached to the DEF injector.

- Remove the DEF line or hose from the injector.

5. Loosen Fastening Bolts:

- Using appropriate tools like a wrench or socket, loosen the fastening bolts securing the DEF injector.

- Carefully store the removed bolts for reinstallation.

6. Remove the DEF Injector:

- Once all bolts are fully loosened, carefully pull out the DEF injector.

- Handle with care to avoid damaging the injector or surrounding components.

7. Inspection and Cleaning:

- Inspect the removed DEF injector for any signs of damage or dirt accumulation.

- If necessary, clean the DEF injector using an appropriate cleaning agent.

8. Install a New DEF Injector (if needed):

- If replacing with a new DEF injector, ensure its model and specifications match the old one.

- Carefully install the new DEF injector into the original position and tighten the bolts securely.

- Reconnect the DEF line or hose, and plug back in the electrical connector.

9. System Reset:

- A system reset is typically done to recalibrate or reset the parameters of a system to ensure proper operation.

- For the 6.7 Cummins engine's DEF injector, a system reset may involve recalibrating or resetting the SCR system.

- Use specialized diagnostic tools or software to perform the system reset, following the steps provided in the vehicle's repair manual or technical documentation.

10. Testing and Inspection:

- After installation and system reset, reconnect power and start the engine.

- Conduct brief testing to ensure the DEF injector is functioning correctly and there are no leaks.

- If needed, perform system diagnostics to ensure all components are operating as expected.

Following these steps will guide you through the process of safely removing the DEF injector on a 6.7 Cummins engine. Be sure to read the vehicle's repair manual thoroughly before starting any work, and always prioritize safety during maintenance procedures.

How to Clean DEF Injector on 6.7 Cummins:

Cleaning the Diesel Exhaust Fluid (DEF) injector on a 6.7 Cummins engine is essential for maintaining optimal performance and emission control. Here's a detailed guide on how to effectively clean the DEF injector:

1. Preparation:

- Ensure the engine is cool and turned off before beginning the cleaning process.

- Gather the necessary tools and supplies, including safety gear such as gloves and safety glasses.

2. Locate the DEF Injector:

- Identify the location of the DEF injector in the emissions system of the 6.7 Cummins engine. It is typically positioned near the exhaust pipe.

3. Removal:

- Follow the steps outlined in the "How to Remove DEF Injector on 6.7 Cummins" guide to safely remove the DEF injector from the engine.

4. Inspection:

- Once the DEF injector is removed, visually inspect it for any signs of dirt, debris, or clogging.

- Check for buildup that may affect the injector's performance.

5. Cleaning Process:

- Prepare a cleaning solution suitable for DEF injectors. This can include a specialized injector cleaner or a mixture of water and mild detergent.

- Place the DEF injector in the cleaning solution and allow it to soak for the recommended time.

- Use a soft-bristled brush or cloth to gently scrub the injector, focusing on areas with visible buildup.

- Avoid using harsh chemicals or abrasive materials that could damage the injector.

6. Rinse and Dry:

- After cleaning, rinse the DEF injector thoroughly with clean water to remove any remaining cleaning solution.

- Ensure all traces of dirt and debris are removed from the injector.

- Allow the injector to air dry completely before reinstallation.

7. Reinstallation:

- Once the DEF injector is clean and dry, carefully reinstall it into the original position on the engine.

- Tighten the fastening bolts securely to ensure proper installation.

- Reconnect the DEF line or hose, and plug back in the electrical connector.

8. System Check:

- After reinstallation, start the engine and conduct a brief test to ensure the DEF injector is functioning properly.

- Check for any leaks or irregularities in the injector's operation.

9. System Reset (if needed):

- If a system reset is required after cleaning the DEF injector, follow the steps provided in the vehicle's repair manual or technical documentation.

- Use specialized diagnostic tools or software to perform the reset, if necessary.

10. Regular Maintenance:

- To prevent future buildup and ensure optimal performance, consider implementing a regular maintenance schedule for cleaning the DEF injector.

- Follow the manufacturer's recommendations for cleaning intervals and procedures.

By following these steps, you can effectively clean the DEF injector on a 6.7 Cummins engine, helping to maintain proper emission control and engine performance. Always prioritize safety and refer to the vehicle's repair manual for specific instructions and guidelines.

How Long Do 6.7 Cummins Injectors Last

The longevity of 6.7 Cummins injectors, especially aftermarket and remanufactured parts, can vary based on several factors. Let's delve into the lifespan of these injectors, particularly those from aftermarket and remanufactured sources:

1. Original Equipment Manufacturer (OEM) Injectors:

- OEM injectors, such as those directly from Cummins or Bosch, are typically designed to last a long time, often reaching up to 150,000 miles or more.

- These injectors undergo rigorous testing and quality control measures during manufacturing, ensuring their durability and longevity.

2. Aftermarket Injectors:

- Aftermarket injectors are those produced by third-party manufacturers, not the original equipment manufacturer.

- The lifespan of aftermarket injectors can vary widely depending on the quality of the manufacturer and the materials used.

- High-quality aftermarket injectors can often last as long as OEM injectors, reaching similar mileage milestones.

- It's essential to choose reputable brands with a track record of reliability for longer-lasting aftermarket injectors.

3. Remanufactured Injectors:

- Remanufactured injectors are OEM injectors that have been disassembled, cleaned, and rebuilt with new components to OEM specifications.

- The lifespan of remanufactured injectors is generally comparable to OEM injectors, often lasting between 100,000 to 150,000 miles.

- These injectors undergo extensive testing and quality control processes during the remanufacturing process, ensuring their reliability.

4. Factors Affecting Lifespan:

- The quality of fuel and lubrication used in the engine can significantly impact injector lifespan. Clean fuel and proper lubrication can help extend injector life.

- Engine maintenance practices, such as regular oil changes and fuel filter replacements, also play a role in injector longevity.

- Driving conditions, such as frequent towing, heavy loads, or stop-and-go traffic, can accelerate wear on injectors.

- Proper installation and torque specifications during injector replacement can also affect their lifespan.

5. Signs of Injector Wear:

- It's essential to monitor for signs of injector wear or failure, such as rough idling, misfires, reduced fuel efficiency, or black smoke from the exhaust.

- If these symptoms occur, it may indicate that the injectors need inspection or replacement.

6. Conclusion:

- In summary, 6.7 Cummins injectors, whether aftermarket or remanufactured, can last a significant amount of time when properly maintained.

- High-quality aftermarket injectors and remanufactured OEM injectors can offer a cost-effective alternative to OEM parts without sacrificing longevity.

- Regular maintenance, including fuel system cleaning, fuel filter changes, and engine tune-ups, can help maximize the lifespan of injectors.

Understanding the lifespan of 6.7 Cummins injectors, particularly aftermarket and remanufactured options, is crucial for vehicle owners and technicians. By choosing reputable brands and following proper maintenance practices, these injectors can provide reliable performance for miles to come.

Conclusion:

In conclusion, maintaining the injectors of the 6.7 Cummins diesel engine is crucial for ensuring optimal performance, fuel efficiency, and emission control. We've covered a range of topics in this maintenance guide, from understanding the basic principles of these injectors to practical steps for removal, cleaning, and extending their lifespan.

-

Overview: The 6.7 Cummins diesel engine relies on precise fuel delivery from its injectors to power a variety of vehicles, from heavy-duty trucks to recreational vehicles and more.

-

Injector Quantity and Programming: We've clarified that the 6.7 Cummins engine is equipped with six injectors, each essential for delivering fuel to its corresponding cylinder. While OEM injectors may require programming, aftermarket and remanufactured options typically do not.

-

DEF Injector Removal and Cleaning: Detailed instructions have been provided on safely removing and cleaning the DEF injector. This process is essential for maintaining emission control and engine performance.

-

Injector Lifespan: Understanding the factors affecting injector lifespan helps vehicle owners make informed decisions. Regular maintenance, high-quality fuel, and proper installation contribute to longevity.

-

Maintenance and Common Issues: Tips for maintaining injectors and addressing common issues have been shared. Regularly replacing filters, using quality diesel, and monitoring for signs of wear are all part of effective maintenance.

In the world of 6.7 Cummins diesel engines, proper injector maintenance is key to a smooth-running vehicle. By following the guidance provided in this comprehensive guide, owners can ensure their injectors last longer, perform better, and contribute to a healthier engine overall.

Remember, if you encounter any issues or have further questions, don't hesitate to reach out. We're here to help you keep your 6.7 Cummins engine running at its best.