Welcome to our in-depth guide on everything you need to know about 7.3 Powerstroke injectors. Whether you're looking to install new injectors, replace old ones, or simply maintain your engine's performance, this guide has you covered. From understanding the different types of injectors to step-by-step instructions on installation and testing, we'll delve into all aspects of 7.3 Powerstroke injectors. Let's get started!

Part 1: Overview of 7.3 Powerstroke Injectors

The 7.3 Powerstroke engine, produced by International Navistar, is renowned for its reliability and longevity. When it comes to injectors for the 7.3 Powerstroke, there are several important factors to consider:

-

Compatibility: 7.3 Powerstroke injectors are designed specifically for Ford trucks equipped with this engine. These trucks include the Ford F-250, F-350, F-450, F-550, Excursion, and E-Series vans.

-

Model Years: The 7.3 Powerstroke engine was available in Ford trucks from 1994 to 2003. This includes both the early 7.3 engines (often referred to as the "pre-99" engines) and the later engines (1999.5 to 2003).

-

Types of Injectors:

- Stock Injectors: These are the original injectors that came with the 7.3 Powerstroke engines from the factory. They are designed to meet the engine's specifications and provide reliable performance.

- Performance Injectors: Upgrading to performance injectors can improve horsepower and torque. These injectors are designed to flow more fuel and are often used in modified or tuned engines.

- Remanufactured Injectors: Remanufactured injectors are rebuilt to OEM specifications. They are a cost-effective option for replacing worn-out or faulty injectors.

-

Features:

- Multi-Hole Nozzles: Most 7.3 Powerstroke injectors feature multi-hole nozzles for improved fuel atomization and combustion.

- Enhanced Durability: These injectors are built to withstand the high pressures and temperatures inside the engine's combustion chamber.

- OEM Quality: Genuine OEM or high-quality aftermarket injectors ensure proper fitment and performance.

Understanding these aspects will help you choose the right injectors for your 7.3 Powerstroke engine, whether you're looking to maintain stock performance or upgrade for more power. In the following sections, we'll dive into detailed instructions on installation, replacement, testing, and more. Stay tuned for valuable insights into maximizing your 7.3 Powerstroke's injector performance!

Part 3: What Are the Best Injectors for 7.3 Powerstroke?

When it comes to upgrading or replacing injectors for your 7.3 Powerstroke, there are several excellent options available. Whether you're seeking improved performance, enhanced fuel efficiency, or better towing capability, aftermarket injectors can make a significant difference. Here are some top choices preferred by 7.3 Powerstroke enthusiasts:

1. Remanufactured Injectors:

- Remanufactured injectors are factory injectors that have been carefully rebuilt to meet or exceed OEM specifications. They offer a balance of reliability and affordability, making them an attractive option for many truck owners.

2. Performance Upgrade Injectors:

- Performance upgrade injectors are designed with larger nozzles and increased flow rates to boost horsepower and torque. They are ideal for those looking to maximize the power potential of their 7.3 Powerstroke.

3. Upgraded Aftermarket Injectors:

- Upgraded aftermarket injectors come with improved designs for better fuel atomization and increased flow rates. They are engineered to provide noticeable power gains and improved fuel efficiency.

Benefits of Aftermarket Injectors:

- Enhanced Performance: Aftermarket injectors can significantly increase horsepower and torque, making your 7.3 Powerstroke more capable on the road.

- Improved Fuel Efficiency: Some aftermarket injectors are designed for better fuel atomization, leading to improved fuel economy.

- Better Towing Capacity: Upgraded injectors can offer increased torque, which is beneficial for towing heavy loads.

- Cost-Effective: Remanufactured injectors provide a cost-effective solution without compromising quality.

Recommendations:

- Bostech Remanufactured Injectors: Bostech offers reliable remanufactured injectors that meet or exceed OEM specifications. They are a trusted choice for quality and performance.

- Sinister Diesel Performance Injectors: Sinister Diesel provides performance upgrade injectors known for their power gains and durability.

- Dynomite Diesel Performance Injectors: Dynomite Diesel offers a range of performance injectors with various flow rates, allowing you to choose the right option for your desired power level.

- Full Force Diesel Injectors: Full Force Diesel is renowned for its upgraded aftermarket injectors, delivering improved performance and fuel efficiency.

Conclusion:

Choosing the best injectors for your 7.3 Powerstroke depends on your specific needs and preferences. Upgraded and remanufactured injectors from reputable brands like Bostech, Sinister Diesel, Dynomite Diesel, and Full Force Diesel offer reliable options for enhancing your truck's performance. Whether you're looking for increased power, improved fuel efficiency, or better towing capability, aftermarket injectors can provide the solution you need. It's recommended to consult with a diesel performance expert to determine the best option for your 7.3 Powerstroke truck.

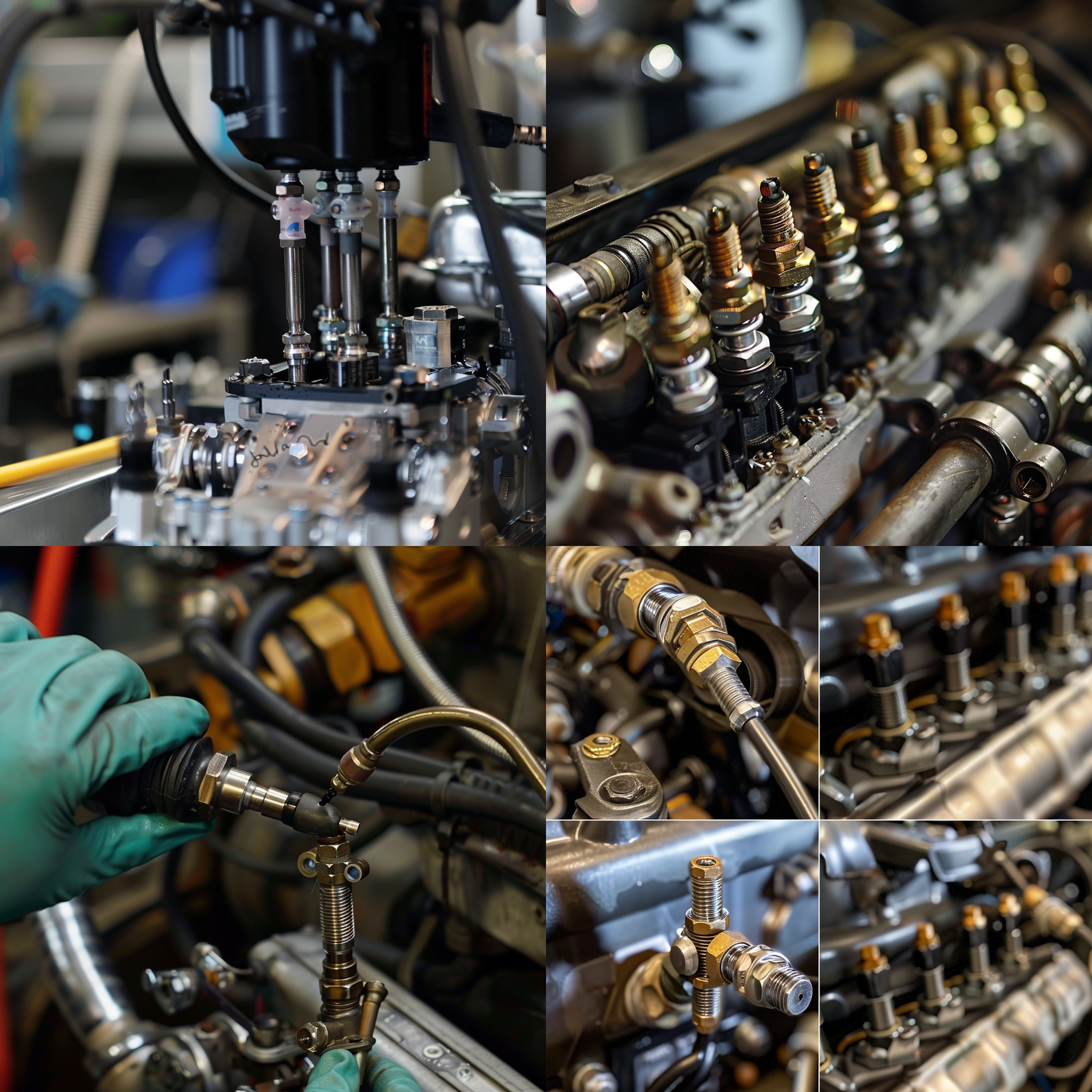

Part 5: How to Properly Install 7.3 Powerstroke Injectors

Installing new injectors on a 7.3 Powerstroke engine requires precision and attention to detail. Here's a step-by-step guide on how to properly install 7.3 Powerstroke injectors:

Tools and Materials Needed:

- New or remanufactured injectors

- Injector o-rings

- Injector installation kit

- Socket wrench set

- Torque wrench

- Clean rags

- Safety glasses

- Gloves

- Engine oil

Steps to Install 7.3 Powerstroke Injectors:

-

Prepare the Vehicle:

- Park the vehicle on a level surface and engage the parking brake.

- Allow the engine to cool down before starting work.

-

Disconnect Batteries:

- Disconnect both negative battery cables to prevent any electrical accidents.

-

Remove Valve Cover:

- Using a socket wrench, carefully remove the valve cover to access the injectors.

-

Clean the Injector Bore:

- Use a lint-free cloth to thoroughly clean the injector bore in the cylinder head. Ensure it's free of debris.

-

Replace O-Rings:

- Remove the old injector o-rings and replace them with new ones. Lubricate the new o-rings with clean engine oil.

-

Seat the New Injectors:

- Carefully seat the new injectors into their respective bores in the cylinder head. Make sure they are properly aligned.

-

Secure with Hold-Down Bolts:

- Secure the injectors by tightening the hold-down bolts to the manufacturer's specified torque.

-

Reattach Fuel Lines:

- Reconnect the fuel lines to the injectors. Ensure they are properly seated and tightened.

-

Connect Wiring Harness:

- Attach the wiring harness connectors to each injector. Ensure they click into place securely.

-

Replace Valve Cover:

- Place the valve cover back onto the cylinder head and tighten the bolts securely.

-

Reconnect Batteries:

- Reconnect the negative battery cables.

-

Prime the Fuel System:

- Before starting the engine, prime the fuel system to ensure the injectors are properly filled with fuel. This can be done using a hand pump or an electric fuel pump.

-

Start the Engine:

- Start the engine and monitor for any leaks around the injectors.

- Check for smooth engine operation and proper performance.

By following these steps, you can effectively and properly install new injectors on a 7.3 Powerstroke engine. Always refer to the vehicle's service manual for specific instructions and torque specifications. If you're uncertain about any step, it's advisable to seek assistance from a professional mechanic.

Part 6: How to Clean Injectors on a 7.3 Powerstroke

Over time, carbon deposits and other contaminants can build up on the injectors of a 7.3 Powerstroke engine, affecting fuel delivery and engine performance. Here's a guide on how to properly clean the injectors:

Tools and Materials Needed:

- Injector cleaning kit (containing cleaning solution and attachments)

- Safety glasses

- Gloves

- Clean rags

- Compressed air

Steps to Clean Injectors on a 7.3 Powerstroke:

-

Prepare the Vehicle:

- Park the vehicle on a level surface and engage the parking brake.

- Allow the engine to cool down before starting work.

-

Disconnect Batteries:

- Disconnect both negative battery cables to prevent any electrical accidents.

-

Remove Injectors (Optional):

- While not always necessary, removing the injectors for cleaning can provide more thorough results.

- Follow the steps for removing injectors as outlined in the appropriate service manual for your vehicle.

-

Attach Injector Cleaning Kit:

- If the injectors are still in place, attach the appropriate injector cleaning kit to the fuel rail.

- These kits typically come with a cleaning solution and attachments to connect to the fuel rail.

-

Run Cleaning Solution:

- With the engine off, connect the cleaning kit to the fuel rail.

- Follow the manufacturer's instructions for running the cleaning solution through the injectors.

- This process usually involves cycling the engine on and off to allow the cleaning solution to pass through the injectors.

-

Use Compressed Air:

- After running the cleaning solution through the injectors, use compressed air to blow out any remaining debris.

- Be careful not to damage the injector tips with excessive air pressure.

-

Reinstall Injectors (If Removed):

- If the injectors were removed, reinstall them following the appropriate service manual procedures.

- Ensure all connections are tight and properly seated.

-

Reconnect Batteries:

- Reconnect the negative battery cables.

-

Prime the Fuel System:

- Before starting the engine, prime the fuel system to ensure the injectors are properly filled with fuel. This can be done using a hand pump or an electric fuel pump.

-

Start the Engine:

- Start the engine and monitor for any improvement in engine performance.

- Check for smooth engine operation and proper fuel delivery.

Regularly cleaning the injectors can help maintain optimal performance and fuel efficiency in a 7.3 Powerstroke engine. If you're unsure about performing this procedure, it's recommended to seek assistance from a professional mechanic.

Part 7: How to Check and Test Injectors on a 7.3 Powerstroke

Regularly checking and testing the injectors on your 7.3 Powerstroke engine is essential for maintaining optimal performance. Here's a guide on how to properly check and test the injectors:

Tools and Materials Needed:

- Diagnostic scanner

- Fuel pressure gauge

- Clean rags

- Safety glasses

- Gloves

Steps to Check and Test Injectors on 7.3 Powerstroke:

-

Connect Diagnostic Scanner:

- Use a diagnostic scanner compatible with the 7.3 Powerstroke engine to read any trouble codes related to the injectors.

-

Check Injector Balance Rates:

- With the engine running, use the diagnostic scanner to check the injector balance rates. These rates indicate the amount of fuel each injector is delivering.

- Compare the balance rates of all injectors. They should be relatively close to each other. If there is a significant difference, it may indicate a faulty injector.

-

Inspect for Leaks:

- Visually inspect each injector for any signs of leaks or seepage around the injector body or fuel lines.

- If there are visible leaks, it's an indication that the injector may need to be replaced.

-

Test Fuel Pressure:

- Use a fuel pressure gauge to test the fuel pressure at the injector rail. Refer to the manufacturer's specifications for the correct pressure range.

- Low fuel pressure can cause injector issues and should be addressed.

-

Perform Buzz Test:

- The diagnostic scanner can also perform a buzz test on the injectors. This test activates each injector to ensure they are functioning properly.

- Listen for a distinct buzzing sound from each injector. If an injector does not produce the expected sound, it may be faulty.

-

Cylinder Contribution Test:

- Some diagnostic scanners can perform a cylinder contribution test. This test identifies which cylinders are not contributing properly.

- If a cylinder shows low contribution, it may be due to a faulty injector.

-

Inspect Injector Harness:

- Check the wiring harness connected to each injector for any signs of damage or corrosion. Faulty wiring can cause injector issues.

-

Professional Inspection:

- If you're unsure about the results of your tests or if you suspect an issue with the injectors, it's advisable to seek assistance from a professional mechanic.

- A mechanic can perform more advanced tests, such as injector flow testing, to accurately diagnose injector problems.

By following these steps, you can effectively check and test the injectors on your 7.3 Powerstroke engine. Regular maintenance and testing can help prevent performance issues and ensure optimal fuel delivery.

Additional Information: How to Buzz Test 7.3 Injectors:

Tools and Materials Needed:

- OBD-II scan tool with injector buzz test capability

Steps:

-

Connect the Scan Tool: Plug the OBD-II scan tool into the vehicle's diagnostic port, usually located under the dashboard on the driver's side.

-

Turn on the Ignition: Turn the ignition key to the "ON" position without starting the engine. This will power up the scan tool and allow communication with the vehicle's computer.

-

Select Injector Buzz Test: Use the scan tool to navigate to the injector buzz test function. This may be located under the "Special Functions" or "Injector Test" menu.

-

Follow On-Screen Instructions: The scan tool will prompt you to follow certain steps, such as turning off the engine, cycling the key, or selecting the number of cylinders. Follow these instructions carefully.

-

Run the Test: Once everything is set up, initiate the injector buzz test using the scan tool. The test will send a pulse signal to each injector, causing them to "buzz" or click. This helps verify that each injector is receiving the proper electrical signal.

-

Listen for Clicking Sounds: As the test runs, listen for clicking sounds coming from each injector. This indicates that the injector is receiving the electrical signal and is functioning properly.

-

Observe the Scan Tool: The scan tool will display the results of the test for each injector. It will indicate whether each injector passed or failed the test.

-

Interpret the Results: A "Pass" result means the injector is functioning correctly. If an injector fails the test, it may indicate a wiring issue, a faulty injector, or other related problems that need further diagnosis.

-

Address any Issues: If any injectors fail the buzz test, further inspection and testing may be required to determine the exact cause of the problem.

Part 8: How Long Do 7.3 Powerstroke Injectors Last?

The lifespan of 7.3 Powerstroke injectors can vary based on several factors, including maintenance, driving conditions, and fuel quality. On average, properly maintained injectors can last anywhere from 100,000 to 200,000 miles. However, it's essential to monitor their performance regularly to catch any signs of wear or failure early.

Here are some factors that can impact the lifespan of 7.3 Powerstroke injectors:

-

Regular Maintenance:

- Following the manufacturer's recommended maintenance schedule, including changing the fuel filter and using high-quality fuel, can extend the life of the injectors.

-

Fuel Quality:

- Poor-quality or contaminated fuel can lead to injector clogging or damage. Using clean, high-quality diesel fuel is crucial for injector longevity.

-

Driving Conditions:

- Stop-and-go driving, towing heavy loads, or prolonged idling can put more stress on the injectors and shorten their lifespan.

-

Injector Design:

- The design and quality of the injectors themselves can also affect their durability. Replacing old injectors with newer, upgraded designs may improve longevity.

-

Proper Functioning:

- Ensuring the injectors are functioning correctly, with balanced rates and proper fuel pressure, can help prevent premature wear.

-

Symptoms of Failing Injectors:

- Watch for signs such as rough idle, decreased fuel efficiency, loss of power, or black smoke from the exhaust. These could indicate failing injectors that need attention.

While 7.3 Powerstroke injectors can last a considerable amount of time with proper care, it's essential to monitor their performance and address any issues promptly. Regularly checking injector balance rates, fuel pressure, and conducting diagnostic tests can help identify problems early and extend the lifespan of your injectors.

Part 9: How to Remove Injectors on 7.3 Powerstroke

Removing injectors from a 7.3 Powerstroke engine is a task that requires precision and care to avoid damaging the engine components. Here's a step-by-step guide on how to properly remove injectors from a 7.3 Powerstroke:

Tools and Materials Needed:

- Socket wrench set

- Injector puller tool

- Safety goggles

- Gloves

- Clean rags

Steps:

-

Prepare the Engine: Ensure the engine is cool before starting work. Disconnect the negative battery cable to prevent accidental starts.

-

Remove the Valve Cover: Locate the valve cover on the top of the engine. Remove the bolts securing the valve cover using a socket wrench. Carefully lift the valve cover off and set it aside.

-

Access the Injectors: With the valve cover removed, you'll have access to the injectors. Each injector is held in place with a retaining bolt or clamp. Locate and remove these bolts or clamps using the appropriate socket.

-

Disconnect Injector Wiring: Each injector has an electrical connector attached to it. Disconnect the wiring harness from each injector carefully to avoid damaging the connectors.

-

Remove the Injector Hold-down Bolts: There are typically two hold-down bolts securing each injector. Loosen and remove these bolts using a socket wrench.

-

Use an Injector Puller Tool: Attach an injector puller tool to the top of the injector. This tool will help you gently lift the injector out of its bore without damaging the injector or the engine.

-

Carefully Pull Out the Injector: Apply gentle upward pressure on the injector puller tool to lift the injector out of the bore. Be careful not to twist or force the injector, as this can cause damage.

-

Inspect the Bore: Once the injector is removed, inspect the bore for any debris or damage. Clean the bore with a clean rag if necessary.

-

Repeat for Remaining Injectors: Repeat the above steps for each injector that needs to be removed.

-

Clean the Injector Ports: Before installing new injectors, clean the injector ports in the cylinder head using a lint-free cloth and a suitable solvent.

By following these steps carefully, you can safely and effectively remove injectors from a 7.3 Powerstroke engine. Always refer to the vehicle's service manual for specific instructions and torque specifications.

Part 10: Are All 7.3 Injectors the Same?

No, not all 7.3 injectors are the same. The 7.3 Powerstroke engine, used in Ford trucks from 1994 to 2003, underwent several changes in injector design and specifications throughout its production run. Here's an overview of the different types of injectors used in the 7.3 Powerstroke:

-

Early vs. Late Model 7.3 Powerstroke: The 7.3 Powerstroke engine transitioned from using single-shot injectors in early models to split-shot injectors in later models.

-

Early Model (Pre-1999): Early 7.3 Powerstroke engines, before 1999, typically used single-shot injectors. These injectors deliver all the fuel in one burst per cycle.

-

Late Model (1999-2003): Starting in 1999, the 7.3 Powerstroke engines used split-shot injectors. These injectors deliver fuel in two stages—a smaller pilot injection followed by a main injection. This design improves fuel atomization and efficiency.

-

-

Injector Sizes and Flow Rates: Within the single-shot and split-shot injector categories, there are variations in injector sizes and flow rates. These differences can impact engine performance and fuel delivery.

-

Aftermarket and Performance Injectors: There are aftermarket and performance injectors available for the 7.3 Powerstroke. These injectors may have different flow rates and characteristics compared to stock injectors. They are designed to cater to various performance needs, such as increased horsepower and torque.

-

Remanufactured vs. New: Injectors can also vary based on whether they are new from the manufacturer or remanufactured. Remanufactured injectors are rebuilt to meet or exceed OEM specifications but may have slight differences compared to new injectors.

-

Electrical Connectors: Additionally, the electrical connectors for the injectors may differ between early and late models of the 7.3 Powerstroke.

In conclusion, 7.3 injectors are not all the same. The type of injector used in a particular 7.3 Powerstroke engine depends on the model year and whether it is an early or late model. It's important to use injectors that are designed for your specific engine model and year to ensure proper fitment and performance.

Part 11: How Do 7.3 Injectors Work?

Understanding how injectors work in a 7.3 Powerstroke engine is crucial for maintaining its optimal performance. Here's a detailed look at the functioning of 7.3 injectors:

Fuel Injection System Overview:

- The 7.3 Powerstroke engine features a high-pressure oil system that operates the injectors. This system provides the necessary pressure to actuate the injectors.

- When the engine is running, the high-pressure oil pump generates pressure that is regulated by the Injection Pressure Regulator (IPR) valve.

- The IPR valve controls the amount of oil pressure sent to the injectors based on input from the Powertrain Control Module (PCM).

Injector Operation:

-

Injection Cycle Initiation:

- When the PCM detects the need for fuel delivery, it sends an electrical signal to the Injector Control Pressure (ICP) sensor.

- The ICP sensor measures the high-pressure oil's pressure and sends this information back to the PCM.

- Based on the ICP sensor's input, the PCM determines the desired injector pressure and sends a signal to the IPR valve.

-

Building Pressure:

- The IPR valve then adjusts to regulate the high-pressure oil flow to the injectors.

- As the IPR valve opens, high-pressure oil flows through the injector's internal passages, building pressure.

- This high-pressure oil acts on the injector's intensifier piston, creating the force needed to open the injector.

-

Opening the Injector:

- When the pressure reaches the required level, it overcomes the injector's internal spring tension.

- The injector solenoid receives an electrical signal from the PCM, causing it to open.

- The injector's poppet valve opens, allowing pressurized fuel to flow into the combustion chamber.

-

Fuel Delivery:

- The high-pressure oil continues to act on the intensifier piston, ensuring the injector remains open.

- Pressurized fuel is sprayed into the combustion chamber in a fine mist, mixing with the compressed air.

- This fuel-air mixture is ignited by the spark plug (in a diesel engine, typically compression-ignition), producing power to drive the engine.

-

Closing the Injector:

- After the required amount of fuel is delivered, the PCM signals the injector solenoid to close.

- The poppet valve seals shut, stopping fuel flow.

- The injector returns to its closed position, ready for the next injection cycle.

Key Points:

- Precision and Timing: 7.3 injectors operate with precision timing and pressure control to deliver the right amount of fuel at the right moment.

- Optimal Combustion: The fine fuel mist ensures complete combustion, maximizing engine efficiency and performance.

- Maintenance: Regular maintenance, including injector cleaning and testing, is essential to ensure proper injector function and engine performance.

Understanding how 7.3 injectors work allows for better troubleshooting, maintenance, and optimization of the engine's performance. Proper care and maintenance of the injectors contribute to the longevity and efficiency of the 7.3 Powerstroke engine.

Part 12: How Many Injectors Are in a 7.3 Powerstroke?

The 7.3 Powerstroke engine, a reliable workhorse known for its durability, features a total of eight injectors. These injectors play a crucial role in delivering the precise amount of fuel required for optimal engine performance.

Injector Configuration:

- The 7.3 Powerstroke engine follows a V8 configuration, which means there are eight cylinders in total.

- Each cylinder is equipped with its own injector, resulting in a total of eight injectors in the engine.

Injector Placement:

- The injectors are strategically positioned in the cylinder head, with one injector per cylinder.

- This placement allows for precise fuel delivery directly into each combustion chamber.

Importance of Eight Injectors:

- The eight injectors in the 7.3 Powerstroke engine work together to ensure smooth and efficient operation.

- Each injector is responsible for delivering fuel to its corresponding cylinder, contributing to optimal combustion and engine performance.

- The synchronized operation of all eight injectors is crucial for maintaining the engine's power output, fuel efficiency, and overall reliability.

Maintenance Considerations:

- With eight injectors, proper maintenance is essential to keep the engine running smoothly.

- Regular injector cleaning, testing, and inspection help ensure each injector is performing optimally.

- If any injector malfunctions or fails, it can lead to performance issues such as rough idling, loss of power, or increased fuel consumption.

- Maintaining the entire set of eight injectors is key to the longevity and performance of the 7.3 Powerstroke engine.

In summary, the 7.3 Powerstroke engine is equipped with eight injectors, one for each cylinder. These injectors work in unison to deliver the precise amount of fuel needed for efficient combustion and engine operation. Proper maintenance of all eight injectors is vital for maintaining the engine's reliability and performance.

Part 13: How Much Are Injectors for a 7.3 Powerstroke and Replacement

The cost of injectors for a 7.3 Powerstroke engine can vary based on several factors, including the brand, type, and whether you're purchasing new or remanufactured injectors. Additionally, the price for replacing all eight injectors will differ from replacing a single injector. Here's a breakdown to give you an idea of the cost:

Cost Factors:

- Brand: There are various brands available for 7.3 Powerstroke injectors, ranging from OEM (Original Equipment Manufacturer) to aftermarket brands.

- Type: Injectors can come in different types, such as stock replacement, performance, or remanufactured.

- Condition: Remanufactured injectors are generally more affordable than brand new ones but still offer reliable performance.

- Quantity: Replacing all eight injectors will be more expensive than replacing a single injector.

Price Range:

- Single Injector: The cost for a single 7.3 Powerstroke injector can range from approximately $100 to $300 or more, depending on the brand and type.

- Full Set of Eight Injectors: If you're replacing all eight injectors, the total cost can range from $800 to $2,400 or more, depending on the factors mentioned above.

Replacement Cost:

- If you're having a professional mechanic replace the injectors, labor costs will also be a factor. Labor costs can vary widely based on location and the mechanic's hourly rate.

- Generally, the labor cost for replacing all eight injectors can range from $500 to $1,500 or more.

Total Cost Estimate:

- Considering both the cost of the injectors and labor, the total price for replacing all eight injectors on a 7.3 Powerstroke engine can range from $1,300 to $3,900 or more.

- It's important to note that these are rough estimates, and actual prices may vary based on the specific circumstances and where you purchase the injectors.

Remanufactured vs. New:

- Opting for remanufactured injectors can offer cost savings without compromising quality. Remanufactured injectors are rebuilt to meet or exceed OEM specifications.

- New injectors may offer peace of mind in terms of warranty and longevity, but they can be more expensive.

Recommendations:

- When purchasing injectors, it's crucial to ensure they are compatible with the 7.3 Powerstroke engine.

- Research different brands and types to find the best balance between cost and quality.

- If you're unsure about the replacement process or the type of injectors to choose, consulting with a trusted mechanic or diesel technician is advisable.

In conclusion, the cost of injectors for a 7.3 Powerstroke engine varies based on brand, type, and quantity. Replacement costs for all eight injectors, including labor, can range from $1,300 to $3,900 or more. Researching options and consulting with professionals can help make an informed decision for your 7.3 Powerstroke injector replacement needs.